The "brains" of hubo are this little PC: A mini-ITX board running an 800MHz Pentium-III. Power is drawn from the distribution board shown below, which can run from any DC source.

The "brains" of hubo are this little PC: A mini-ITX board running an 800MHz Pentium-III. Power is drawn from the distribution board shown below, which can run from any DC source. The hubo computer runs Windows XP; besides being a familiar environment, this feature makes it easy to connect to (USB, serial), move data, and debug with a keyboard and mouse.

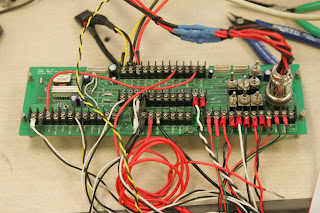

These parts make up the testing station. Motors, controllers, IMU's and force sensors interface just like they would on a normal hubo. The 2 small wires (yellow and black) connecting to the ITX board are the CAN interface, which connects the computer to all the peripherals in the system. This begs the question, what is a CAN and why is it used? A good technical summary can be found here (wikipedia). Practically, the advantages are clear: A CAN bus allows many different compatible devices to communicate over the same data lines. Each transmission packet has an overhead of about 6 bytes, and can transmit 0-8 bytes. The extensive header information gives each packet a unique encoding. Devices on the line can then be programmed only to receive or transmit data with a certain address. Wiring topology is thus determined by software, rather than hardware, making it easy to add/change sensors and drivers.